Do I Need a Power Distribution Module (PDM)?

Published by Chief Enterprises on Jan 10th 2024

Wondering whether a Power Distribution Module (PDM) is right for your application? If you're in the process of designing your vehicle’s electrical system, these questions may sound familiar:

- Do I need a PDM?

- Will it benefit my build?

- How do I know if it's necessary?

Let’s explore four key scenarios where a sealed PDM can make a significant difference—along with real-life examples showing how they’re used in the field.

- You need to localize a power source

Vehicle electrical systems grow more complex with every model year. Routing large wiring harnesses to a single centralised power source is not only costly but also cumbersome. A more efficient solution is to localise power using distributed PDMs.

A sealed, hard-wired PDM allows you to house essential plug-in components, such as fuses, relays, and diodes, in compact, weather-resistant enclosures located close to the point of use.

Example:

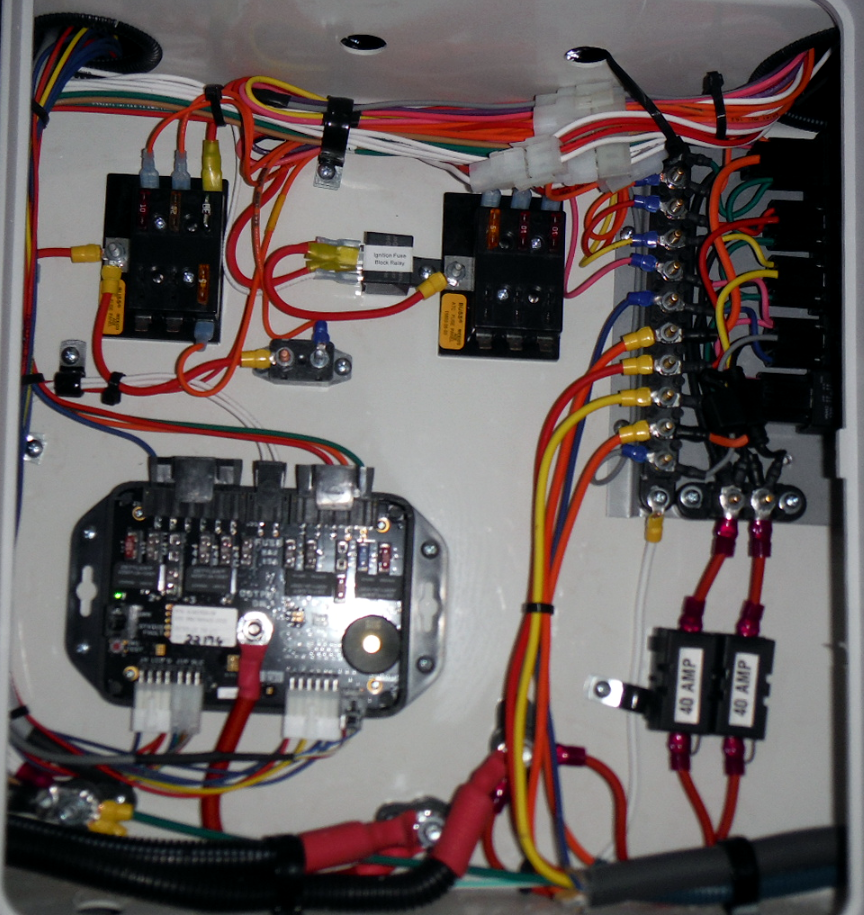

Below is an image of a PDM integrated into the power control panel of a zero-turn mower, optimising local power distribution.

.

.

- You need to simplify your wiring

By localising power, you naturally reduce the length and complexity of your wire harnesses. This not only simplifies the overall design but can also reduce:

- Assembly time (and related labour costs)

- Component count and installation errors

Example:

See the before-and-after image of a control panel upgraded with a PDM. The simplified layout enhances serviceability and lowers production time.

- You need the option to expand functionality

We all know a project design is rarely ever “finished.” New requests, whether from stakeholders or end users, often emerge post-design.

That’s why it’s smart to plan for future scalability. Power distribution modules come in flexible configurations, offering spare cavities to easily add circuits without taking up additional space.

Example:

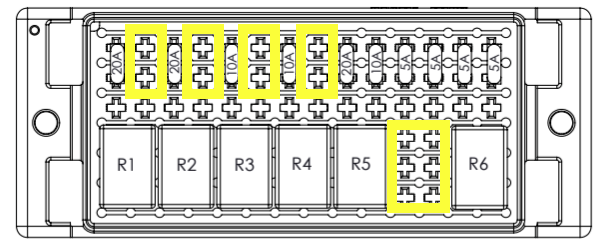

The image below shows a PDM schematic with unoccupied cavities, ready for future expansion without redesigning the enclosure.

- You need to protect electrical components in a sealed enclosure

From construction vehicles to snow equipment, harsh environments pose real challenges for electrical reliability. Regulations and field performance both demand robust protection.

Sealed PDMs safeguard sensitive components, like fuses, diodes, and relays, from water, dirt, salt, and debris, ensuring long-term durability in demanding conditions.

Example:

Here’s a PDM mounted on a stand-up snow plough, where freezing temperatures and exposure to the elements make sealed protection absolutely essential.

If one or more of these scenarios resonate with your build, it’s time to consider integrating a power distribution module into your design. Chief Enterprises offers a complete line of sealed PDMs under the BRIC family, Breathable & Robust Interconnection Centres, engineered for durability, modularity, and ease of installation.