Der BRIC® spart dem führenden Bushersteller 45 Minuten Arbeitszeit

Published by Chief Enterprises on Feb 6th 2020

Revolutionising Glaval’s Shuttle Bus with the Chief-Engineered BRIC: A Smarter Electrical Strategy

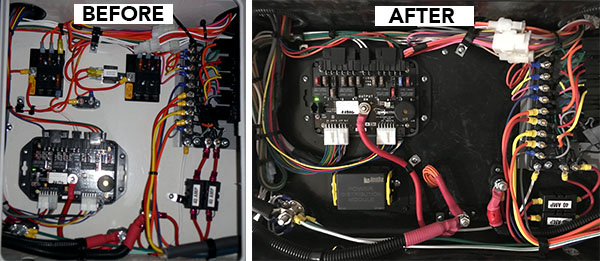

A Complex Puzzle: Glaval’s shuttle buses were facing a common challenge: their electrical systems relied on numerous individual components. Each one demanded its own space, separate inventory management, and carried its own warranty liabilities. On top of that, the time and cost involved in assembling these systems made the entire process inefficient and increasingly unsustainable.

Finding a Solution: When Glaval approached Chief Enterprises for support, they were introduced to the BRIC®—a modular electrical unit that was still in its early stages. “Our contact at Chief showed us the BRIC® prototype, and we were immediately drawn to its simplicity and efficiency,” a member of the Glaval team recalls.

Why the BRIC® Stood Out: By making only minor adjustments to fuse specifications, Glaval was able to transition to a single, unified component. The BRIC® was readily available off the shelft and could be installed with ease. But its true value came from the benefits it delivered:

- Labour time reduced by 45 minutes per unit

- Significant savings on space within the electrical panel

- Fewer wiring errors, resulting in lower warranty risks

The decision to shift to the BRIC® was straightforward in the end. “We were initially a bit cautious, as adopting any new product involves some risk. But once we witnessed the space and cost savings, we knew it was the right move.”

Partnering with Chief: Glaval’s experience with Chief Enterprises was marked by close collaboration and smooth execution. “The support from Chief was outstanding,” they shared. “We couldn’t recommend the BRIC® more highly—not just for the technology, but for the team behind it.”