Strom für die Zukunft: Warum DC-Schütze für die Entwicklung von Elektrofahrzeugen unverzichtbar sind

Published by Chief Enterprises on Jul 13th 2023

Direct Current (DC) contactors are electromechanical devices engineered to switch and control DC electrical circuits. With the unique requirements of DC power—steady current flow and a consistent voltage level—DC contactors have been purpose-built to manage these demands safely and effectively.

Their ability to handle high-voltage, high-current loads makes DC contactors particularly well-suited to the fast-growing electric vehicle (EV) market.

How Do DC Contactors Work?

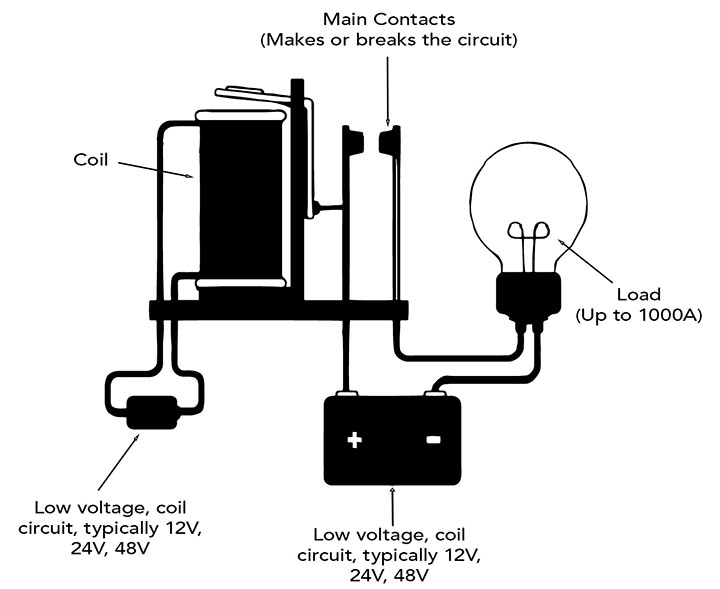

At their core, DC contactors function as high-voltage switches. When a control voltage is applied across two external terminals, an internal coil is energised, generating a magnetic field. This field either attracts or repels a movable contact, closing or opening the circuit path accordingly.

This process transforms the contactor into a rugged, high-power electromechanical switch capable of operating under demanding electrical conditions.

Why DC Contactors Are Ideal for EV Applications

- High Current & Voltage Handling Capabilities: Modern DC contactors can manage currents exceeding 500 Amps and are rated for up to 2,000 Volts. To achieve this, they’re designed with specific safety and performance features:

- Sealed housings: Made from ceramic or high-grade resin and certified to IP67, these enclosures prevent arc leakage and retain internal gases for performance stability.

- Inert gas-filled arc chambers: Gases like hydrogen help suppress electrical arcs, resist oxidation, and maintain low internal resistance—especially critical during high-load switching.

- Magnetic Arc Blow-Out Technology: A key feature of advanced DC contactors is magnetic arc blow-out, achieved through permanent magnets within the arc chamber. These magnets drive the arc outward as the contacts open, helping to extinguish it quickly. This dramatically reduces contact wear and extends the lifespan of the contactor.

- Built-in Coil Economiser: Switching large loads demands significant energy, but once a contactor is closed, only a fraction of that power is needed to hold it in place. A coil economiser, typically using Pulse Width Modulation (PWM), reduces ongoing energy draw and heat build-up, improving thermal management and system efficiency.

Where Are DC Contactors Used in EV Systems?

DC Contactors are a vital part of ensuring safe and effective power distribution across the vehicle’s electrical infrastructure. They are used in numerous high-voltage EV applications, including:

- Main power contactors

- Auxiliary power circuits

- Battery disconnect units (BDUs)

- Charging stations and pre-charge contactors

- Energy storage systems and battery packs

Key Considerations When Selecting a DC Contactor

- Voltage and Current Ratings: Begin by identifying your system’s rated insulation voltage and operating current. Bear in mind that actual performance will also depend on factors like contact material, resistance, contact force, and input voltage. Ensure your specification accounts for variation under real-world conditions.

- Circuit Inductance and Short-Circuit Risk: The inductance of the system impacts the contactor’s breaking capacity. Additionally, the main fuse must be correctly matched to the contactor to avoid damage under fault conditions. Poor matching can lead to thermal or electrical failure during a short circuit.

- Service Life Requirements: The expected number of switching cycles should also be considered. Automotive applications may require no-load or low-load switching, while industrial setups often demand full-load operational durability. Always choose a contactor aligned with the service life expectations of your specific use case.

Chief Enterprises & DC Contactor Solutions

Chief is the value-added distributor for Altran Magnetics, providing engineering support and design integration services. We offer:

- Custom pigtail assemblies

- Pre-configured kits

- Custom mounting solutions

- Rapid prototyping support

For more information about DC Contactors and how Chief can help mitigate your design challenges, please contact us or shop DC Contactors on our web store.